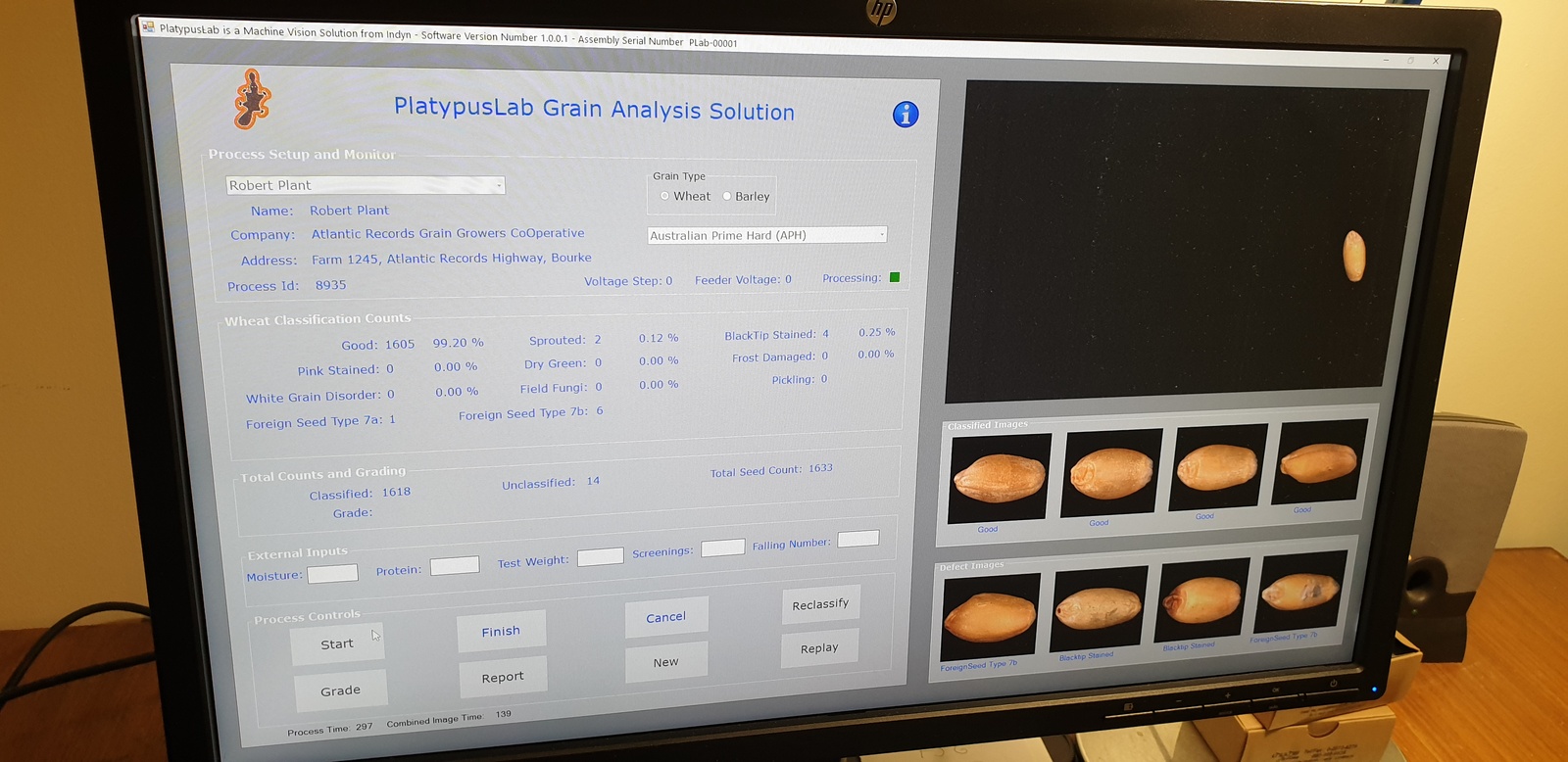

Platypus photographs and assesses around 10,000 grains per sample. Photo: Indyn

IN THIS last story in our series, we look at how two Australian companies, Cropify and Indyn, and Denmark’s FOSS, are using machine learning and artificial intelligence.

As the company behind Infratec, the market leader in analysis equipment used at receival sites around the world, FOSS is looking at artificial neural networks to add depth to its offering.

Cropify is close to commercialising its technology developed initially for lentils and being road-tested on other pulses, while Indyn is working on cereals following its success in other sectors including packaging and horticulture.

Along with GoMicro in Adelaide and ZoomAgri in Perth, these companies are making significant inroads into the efficiency and accuracy of grain-sample assessments.

However, humans as guiders of AI, and as the ultimate quality controllers, are far from disappearing from the grain-quality picture.

Cropify

Started by husband-and-wife team Andrew Hannon and Anna Falkiner in 2019, Cropify was established to bring AI to grain sampling.

Based in Adelaide, Cropify has worked with another South Australian company, Australian Grain Export, to develop AI for Australian product through hi-resolution imaging.

It is also working with global testing, inspection and certification company AmSpec, and Ms Falkiner said Cropify’s latest round of bench testing with a major bulk handler has seen the platform perform “extremely well”.

“Cropify classified in line with the samples provided by the bulk handler that had been classified and had known test results,” Ms Falkiner said.

“Cropify is also accurately identifying weed seeds.”

Cropify last year received a boost from the SA Government’s AgTech Growth fund to develop a smart classification system for small red lentils as the prototype for objective measurement of other pulses.

“Our target is every part of the supply chain that does classification.”

Cropify co-founders Andrew Hannon and Anna Falkiner. Photo: Eliza Hannon

Ms Falkiner said Cropify was eyeing a market that stretched from behind the farm gate to outturn for export.

“We’re looking to prove our capabilities within our local area, and then go into New South Wales and Victoria.”

Ms Falkiner said for growers, Cropify will offer an approach to marketing that differs from the current, where loads pitch at particular specifications, and risk being downgraded if they fail any one of them.

“With Cropify, you’ll be able to send images to your broker and ask: ‘Where can I sell this?’”

Ms Falkiner said Cropify was looking at leasing hardware and having a subscription for software.

“We’re trying to make it a lease agreement; we don’t want obsolete versions out there.

“We hope to have lentil, faba bean and chickpea modules available in February.”

Cropify is looking to open its first stage of investment ahead of the 2023-24 harvest.

“We’re ready to accelerate.”

Indyn

Indyn has developed the Platypus grain-analysis system, named after the monotreme which is often used to describe an unconventional creation.

Indyn co-founder and chief executive officer Rob Martin said the company’s move into grain AI came out of a much bigger target: coconuts.

The coconut connection saw the company shift to Thailand, concurrent with a name change to Industrial Dynamics, or Indyn, from the original Industrial Photonics adopted in 2008.

The company’s hardware and software is already widely used in a range of applications worldwide, including quality control for pharmaceutical and food packaging, and pattern-matching in flooring.

Indyn’s Sydney office was set up to work in grain AI, and work started in 2017 following an approach from Grain Trade Australia as it investigated options for using AI as a supplement to human assessment.

“We use line-scan cameras, one line at a time like the photocopier; the advantage is we can take hi-res images, and we combine that with AI.”

The Platypus has been built to look at samples containing 10,000 seeds over several minutes, and Mr Martin said most of the up-country work Indyn has done to date has been at bulk storages in Moree, Temora and Newcastle.

Platypus software has designed to keep learning, because weather, pathogens and other factors make each harvest different.

“Just when you’ve seen all the varieties, the season changes, and you’re looking for different things.”

For this reason, the Platypus can be run in a supervised or unsupervised mode.

“The machine is designed to be an aid, not an arbiter; it gives you an opinion, and if you want to check the images, you can.”

Following work with seed company AGT, Platypus has had success in identifying varieties.

It has also been able to identify some pests and defects.

“It’s been built for grading or valuation at a receival terminal, and we’ve had interest from all over the place, including Canada and the US.”

“Wheat and barley are the two we’ve done so far, and sorghum, chickpeas and lentils we’re looking at.”

With its small, black and remarkably uniform seed that gives little away visually, Australia’s major oilseed looks like being the trickiest for AI assessment.

“The only one we know that’s going to be difficult is canola.”

The Platypus prototype was finished in 2019, and is now seen as having potential to assess exported grain at despatch and arrival.

“In terms of biosecurity, if a boat gets loaded to certain specifications, then there is no argument at the other end.”

Mr Martin said potential AI in Australian trade, and for the Department of Agriculture, Fisheries and Forestry as the eyes of import and export standards, are huge.

“They’re on a mission…to find insects and other phytosanitary risks in samples, and the technology exists to do it.”

FOSS

Through its EyeFOSS range, FOSS equipment is used in research by government departments, plant-breeding companies and others to provide insights into all kinds of seeds from grain, pulse and oilseed crops.

For all of its accuracy, sources in the grain industry have told Grain Central the equipment is slow and expensive, so therefore unsuitable for commercial use in the grain supply chain.

FOSS is therefore looking at establishing itself in the middle ground between the high-end EyeFOSS and the work-a-day Infratec ranges with artificial neural networks (ANN).

Inspired by neuroscience, ANN looks to capture some of the brain’s extraordinary ability to recognise patterns and make decisions.

FOSS is investigating the combination of ANN with information gleaned from near-infrared (NIR) data.

One scenario examined focused on wheat of 7-24 percent protein over more than 40,000 samples collected globally over 25 years, and of numerous varieties.

Development is being done at the FOSS Innovation Center in Denmark.

The major industries FOSS works in are great, meat, dairy and stockfeed.

Click on the links below to read the previous stories in this series:

Grain AI: Cautious adoption under way

Grain AI: ZoomAgri brings insights to barley ID

Grain AI: GoMicro shapes up as farmers’ friend